|

1943 This is

a |

|

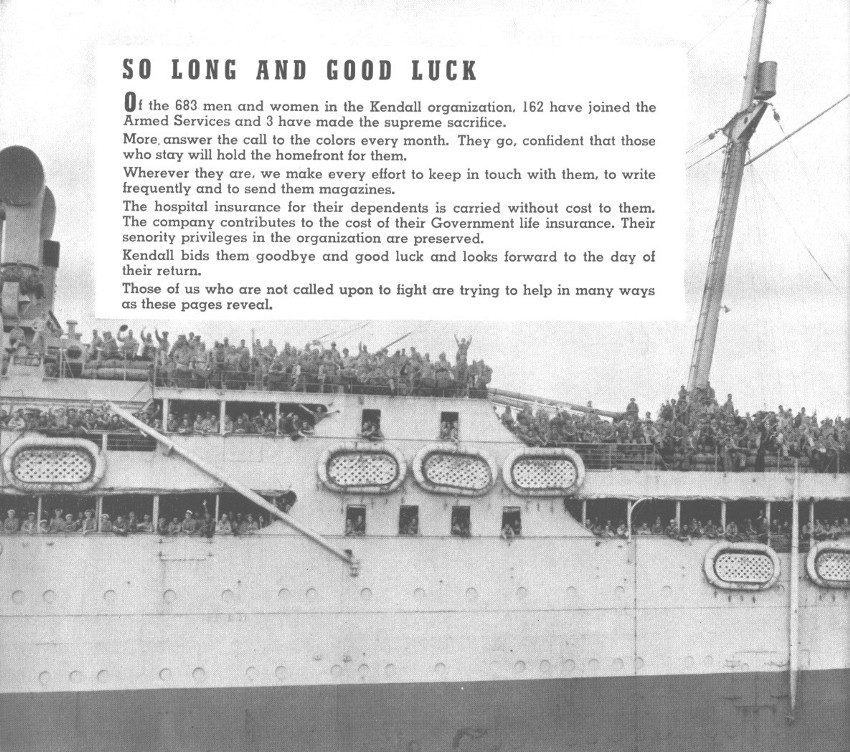

It is not the story of Kendall men on the battlefields - yet certainly they will read it with pride. It is not the story of the Kendall distributor and dealer organization or their contributions to maintaining essential transportation on the homefront. However, to these men it will afford good reading and supply the reasons for the shortages and sacrificies they have had to undergo. It is the story of Kendall products and the contribution they are making toward victory! We submit it as tangible proof of

the accomplishments of Kendall men and women in answering war's

call for a tremendous volume and range of high quality, highly

specialized petroleum products. |

|

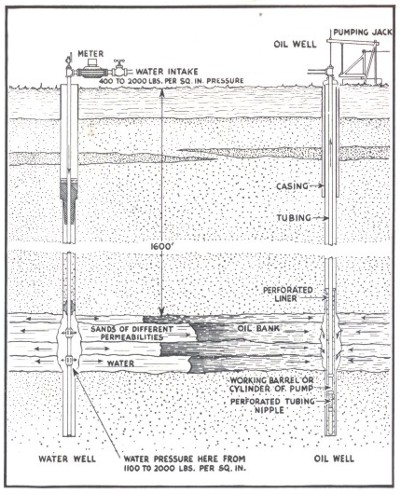

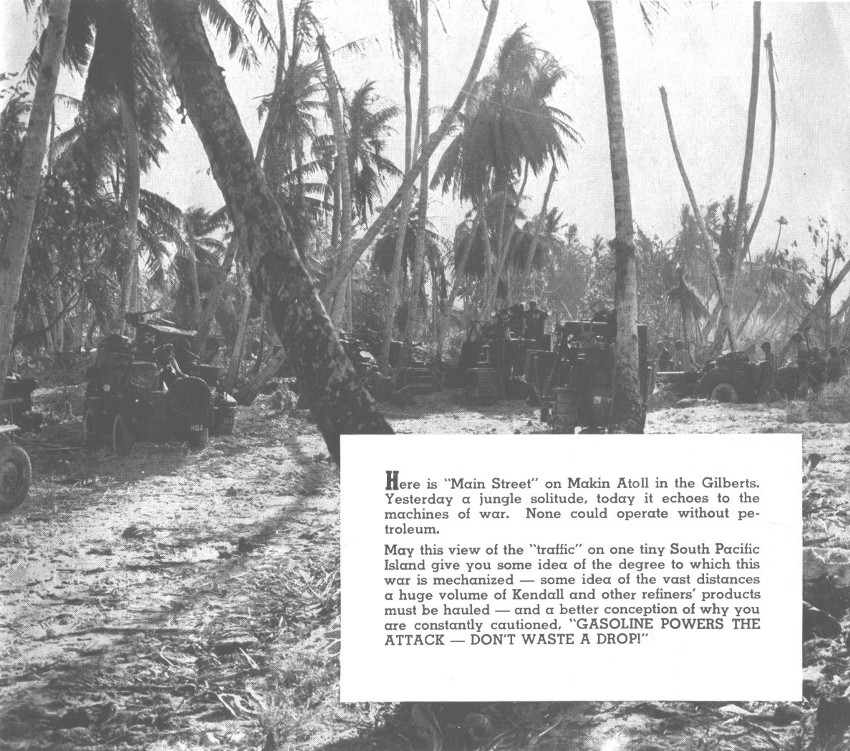

What has a 5-Spot to do with winning the war? Petroleum was a winning weapon in World War I when we "floated to victory on a sea of oil." Today it is many times more important. Not only must we float, we must fly! Even ground warfare has become a matter of mechanized might. Petroleum production had to increase. Every well had to be worked to the utmost. Here's where the 5-Spot comes in. Kendall and other progressive Pennsylvania producers utilize a means of secondary recovery know as the 5-Spot Method. Each oil producing well becomes the center of a square. At each corner of the square a water intake we is drilled. Water forced down these wells into the oil sand drives the oil ahead of it into the producing well. From here it is pumped to tankage. Thus has Kendall helped meet a crying need for higher quality petroleum products through a very substantial increase in the production of Bradford, Pennsylvania crude-top quality crude of them all! |

|

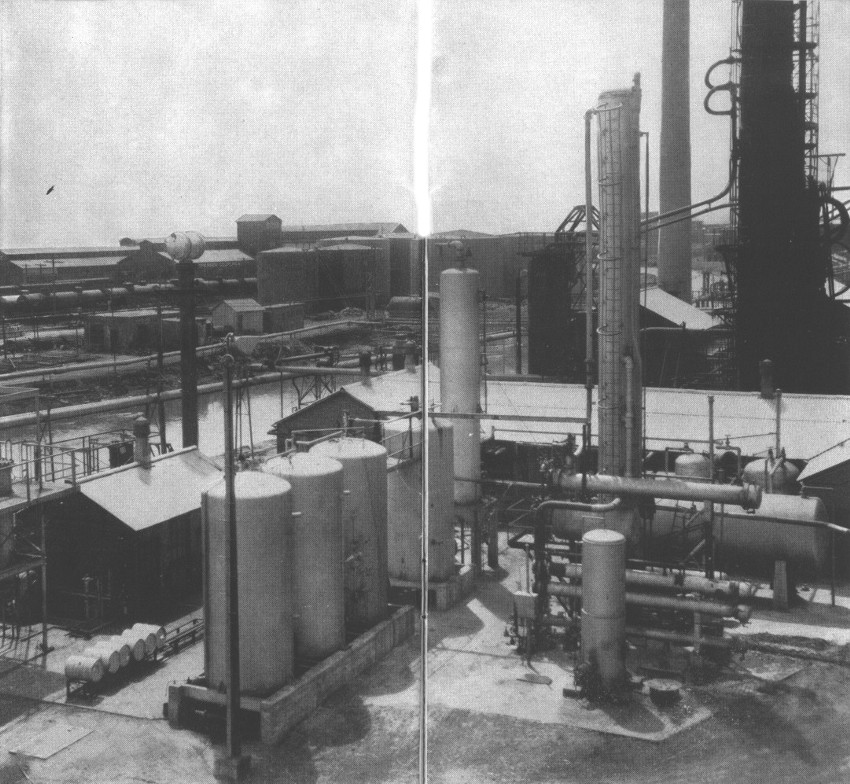

CODIMER FOR

FIGHTING FUELS and COKE FOR MAKING MUNITIONS

Partial view of Kendall Codimer and Coke producing unit. |

| The superiority of our Air Forces stems

from American supplies of high octane aviation gasoline. The chemistry

of this fuel is highly complicated, requiring large amounts of a

hydrocarbon called iso-octane. Kendall supplies substantial quantities

of iso-octanes for the production of aviation fuels in the form

of a product called Codimer. To produce it meant the installation

of special equipment at our cracking plant normally producing Polly

Power Gasoline, the modification of present equipment, the alteration

of our charging stock and many sacrifices in the production of our

normal products. All have been made gladly as another Kendall contribution

to America's war effort! Also vital to the war effort is the manufacture of electrodes used in the reduction and production of aluminum and alloy steels. These electrodes are largely composed of petroleum coke-basis of the entire electro-chemical and electro-metallurgical industries. The coke must be low in ash. The ash content of Kendall coke is one of the lowest in the world. Kendall coke owes its superiority to the crude from which it is made. Like all Kendall products, it is refined from Bradford, Pennsylvania crude oil, the choicest in the world. Producing a coke freer from impurities than any other in this country, Kendall again serves the war effort with a better product giving better results. |

|

|

AVIATION OIL

... of the finest quality ... by the millions of gallons!

|

| Born in aviation's barnstorming 20's, the quality of Kendall Aviation Oil won quick recognition. During the following decade of National Air Races, over 85% of the winners each year used this great lubricant. Constantly improved by thousands of hours of field and laboratory tests, it helped make possible the miracle of our present air superiority. Long before Pearl Harbor, Kendall was shipping Aviation Oil to our Armed Forces. One of our most famous aircraft engine manufacturers has, for 10 years, used Kendall Oil exclusively in the development of an engine that is in the news now. Today, we willingly sacrifice other products and uses to the call for more and still more of this great oil which has become, in point of volume, Kendall's greatest contribution toward helping to win the war. |

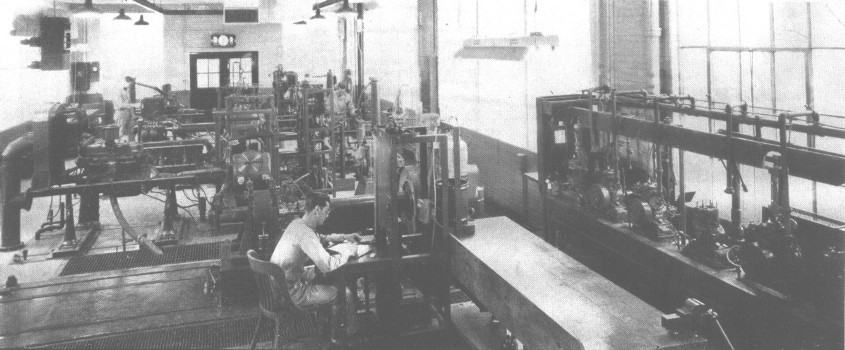

Chevrolet, Ford, General Motors and Caterpillar diesels - oil test engines in Kendall's laboratory |

|

HEAVY DUTY

OIL ... first to go "on duty" from the Pennsylvania

fields

|

| Hard on the heels of war came new government specifications on Heavy Duty Oil for all mechanized field service. In "Fleetlube," product of years of research and millions of miles of tests, Kendall had the quality, was the first Pennsylvania refiner to meet the new specifications. Next problem was quantity. Every Kendall man and woman went to work on that one. Stocks were diverted from other uses. Refining processes were changed to increase the yield. Research was intensified to find new processes. Packaging, handling, shipping, machinery and labor resources were concentrated to answer the call of the armed services. Complete research data on Kendall "Fleetlube" were furnished other Pennsylvania refiners that they might augment the supply with their facilities. The Kendall organization is justly proud that, when the Army announced its specifications for Heavy Duty Oil, "Fleetlube" was ready and went quickly off to war. |

|

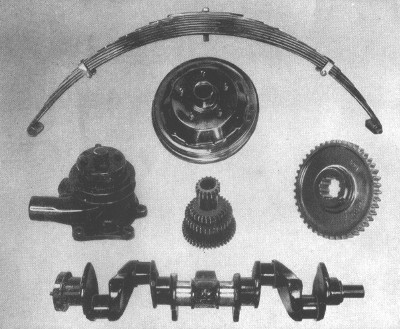

A GEAR LUBRICANT WITH A LIEUTENANT-GENERAL'S RATING "Give us one Gear Lubricant that

will do the work of three!" A tall order from the War Department.

An order for a gear lube that would be equally effective for service

in any climate from the tropics to the arctics. Kendall produced

it in Three Star Gear Lube - the only product ever to meet this

specification. |

|

FOR THE PROTECTION

OF EVERY G.I. JOE ...

|

|

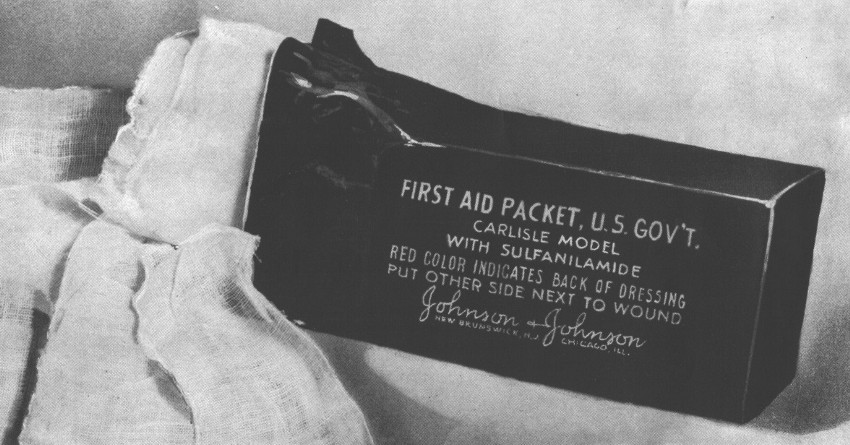

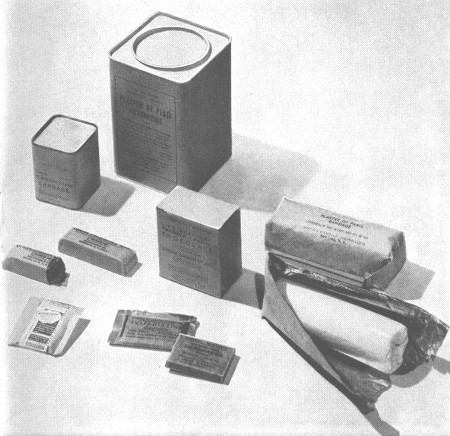

| Every G.I. Joe carries an emergency first aid sterilized wound pad with an envelope of sulpha powder. It's wrapped in an air-tight, moisture-proof, bacteria-excluding cover of paper and foil, held together by a laminating compound made by Kendall. A new, useful development of Pennsylvania petroleum - this Kendall laminating compound helps wrap burn compounds, dressings, dehydrated foods, chocolate, plaster of Paris, ammunition, bibles, batteries and countless other items contributing to the sustenance and safe return of our enlisted men. |

|

FOR THE AIR FORCE . . . . . . . . . In addition to aviation oil, Kendall produces the only compound found satisfactory for sealing vacuum molds in which magnesium aircraft castings are made. Kendall specialty products fly the skies as essential components of transformer and condenser sealing compounds . . . . adhesives for combining electrical insulation papers to varnished cambric . . . . laminating compounds holding together protective wrappings for ammunition and as rust preventatives for replacement parts and assemblies. |

|

|

FOR THE SIGNAL CORPS . . . . . Kendall base materials are in components utilized by the Army Signal Corps in audio radio equipment for the protection or insulation of vital electrical parts. Similarly, Bureau of Ships of the Navy Department uses Kendall materials in connection with products for communication. |

|

FOR CHEMICAL WARFARE SERVICE . . . . Military censorship precludes the details of Kendall contributions in this field other than the use of our base material in incendiary bombs. |

|

|

FOR THE NAVY . . . . . Kendall is a supplier of a very vital Naval anti-aircraft gun gear lubricant. Kendall Rust Preventives are used on aircraft guns and our base materials are used in the protection of Naval medical supplies. These Kendall materials are also in various types of electrical equipment utilized on submarines and in the installation of these daring undersea raiders. |

|

FOR THE CORPS OF ENGINEERS . . . . . It's the job of the engineers to carve roads out of rubble and airfields out of teeming swamp-jungles. Equipment such as bulldozers, tractors, graders, rollers and spreaders does the work. It's hard going and there is a frequent need of replacement parts. Many of those parts reach these advance bases protected by Kendall Rust Preventatives. |

|

|

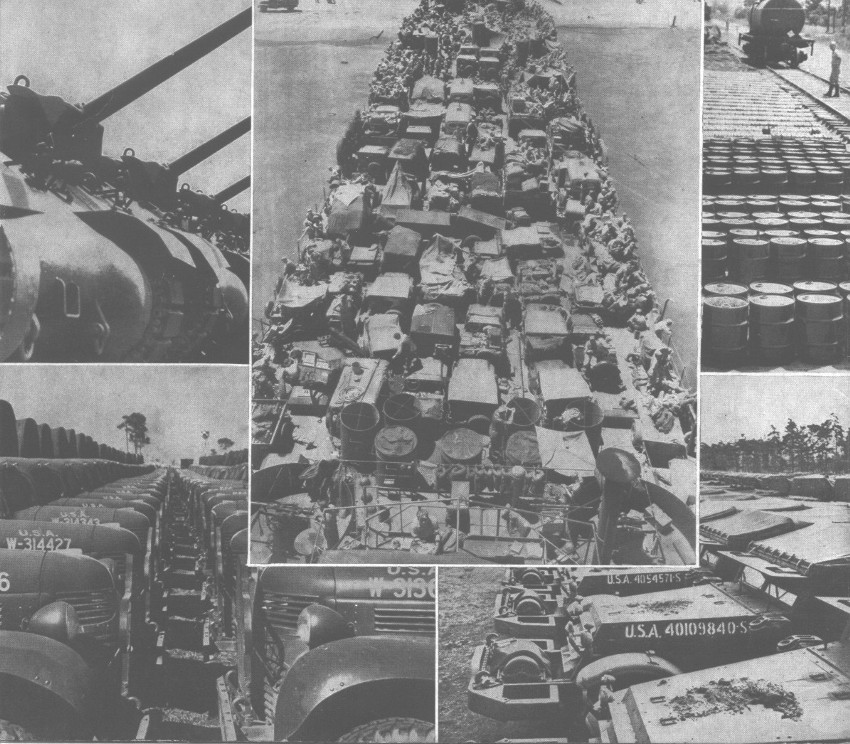

FOR THE ARTILLERY . . . . . Artillery today means mobile firepower - self-propelled big guns, field pieces drawn by four-by-fours or six-by-sixes, motorized anti-tank guns - all requiring heavy duty oils and gear lubricants. In many of them, Kendall lubricants are used. Kendall also supplies materials for the preservation and packaging of tools, spare parts, accessories and equipment vital to the continued operation in the field of these heavy units. |

|

FOR THE TANK CORPS . . . . . Tank manufacturers use Kendall products in the preparation of metal material for shipment abroad. For the gruelling work of tank operations in the field, Kendall refines heavy duty engine oils and gear lubricants. |

|

|

FOR THE MEDICAL CORPS . . . . . Kendall materials are used as laminants in protective wrappings for drugs, bandages, emergency rations and a host of medical items. They bind together leaf metal and paper to exclude moisture and germs. Burial bottles, each containing the identification tag, are sealed with a compound of which Kendall material is a part and interred with the soldier's body. |

|

|

|