|

NATIONAL MUNITIONS

COMPANY

Eldred Buildings 28, 29 & 30: Fuse Lines |

|

|

The

loading operations on the Fuse Lines were carried out in three

buildings - Buildings 27, 28 & 29. Originally these buildings

were connected by corridores, but those sections were filled in

so as to constitute a continuous uniform structure 465 ft long.

Number 119 fuses are loaded at this end (No 28). Number 152 fuses

are loaded at the other end (No 29) and Building No 27 in the

middle served as a receiving and unpacking building. This view

is looking north.

|

|

|

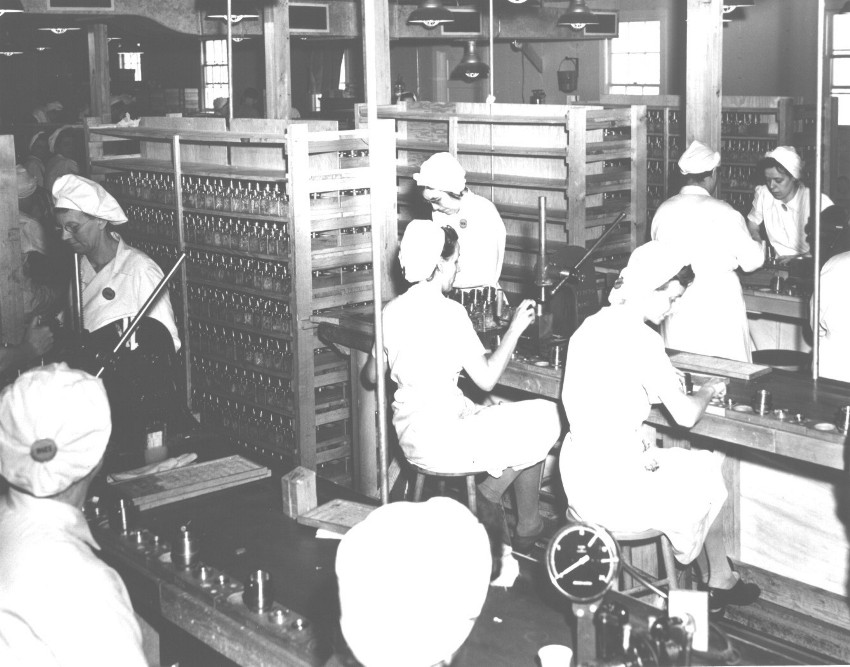

#119

Fuse Breakdown

View showing part of the breakdown lines. The fuse bodies must be disassembled and made ready for loading. The component parts of each fuse are kept separate and placed in blocks which pass down the loading line. |

|

|

View

of the other half of the #119 Fuse breakdown lines.

|

|

|

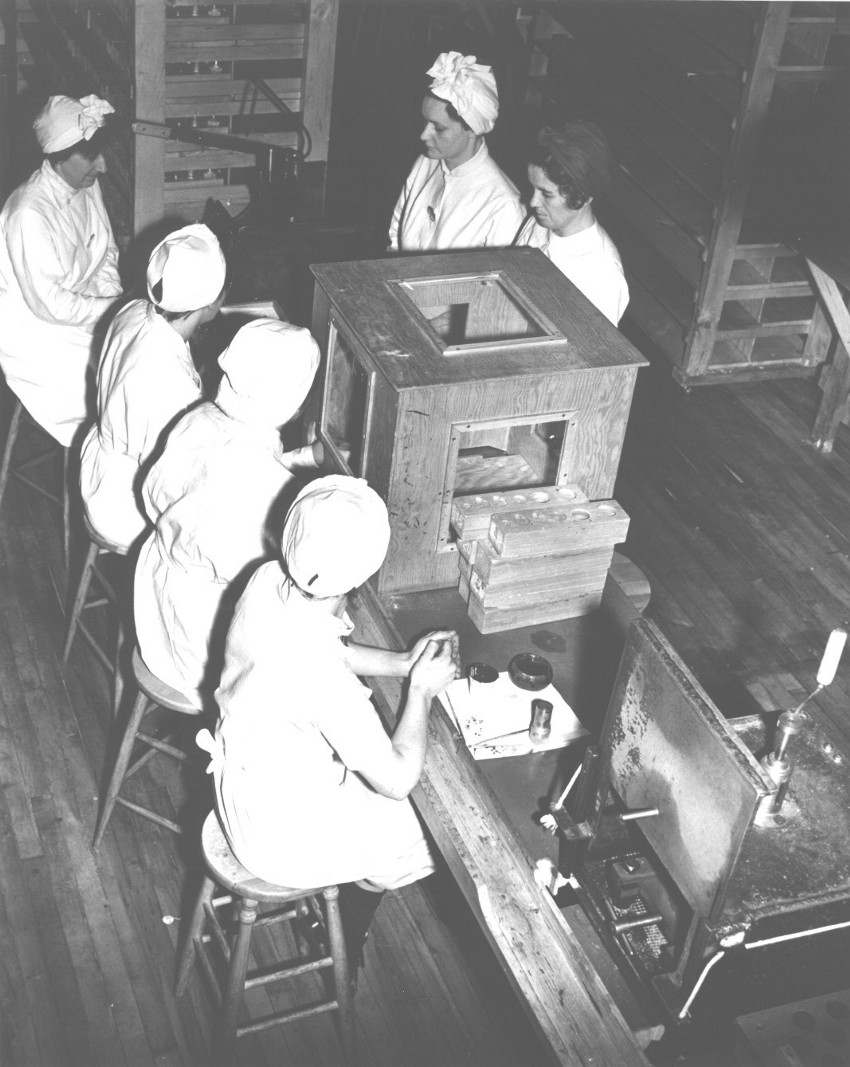

Shutter Cleaning and

Preparation

In the #119 Fuse, the shutter has to be removed from the magazine, cleaned and scraped, and papered on one side with a special paper before it can be stemmed. This view shows those operations being done. |

|

|

#119 Fuse Line

View showing operations on a part of the #119 Fuse Line. Stemming of shutters and fire channels is done inside so called "Lighthouses." Note girls hands at left, through the lighthouse window engaged in stemming of fire channels. Machine at right are for crimping detonator holders. |

|

|

#119 Fuse Line

View showing banks of fuses at left drying after paper disks on firing channels and shutters have been shellacked, and machines for stabbing the five grain detonator holders center. Note the blocks used for holding fuse and components as they are slid down the channel of the work tables. |

|

|

Shutter Spinning Detail

View of spinning device for testing shutters. Shutters must arm when revolved at between 1300 and 1700 revolutions per minute. Note dial of center machine showing spinner revolving at a little over 1500 revolutions per minute. |

|

|

Base Cap Crimping Machines

After the booster pellet has been placed in magazine of the #119 Fuse, and the cap screwed on, the cap is crimped in these crimping machines. The metal door is closed before the crimping operation is performed. |

|

|

Luting and Shutter

Papering

View of part of #119 Fuse Line showing at the right the papering and inspection of shutters, and at the left the luting being applied. Tightening and crimping machines may be seen in the background. |

|

|

#152

Fuse Line

View of two of the #152 Fuse production lines. In the foreground the fuses are being broken down or disassembled. Stemming of the disks is being done in the "lighthouses" and papering by the operators next in line. The drying banks may be seen in about the middle of the lines. |

|

|

Detonator Crimping

Close up view of part of #152 Fuse Lines. The detonator crimping machine may be seen at the top. The pellet is inserted inside the "lighthouse" and the machine for tightening the base plug is shown at the bottom of the picture. |

|

|

Another

view showing the crimping of the detonator in the shutter, inserting

the shutter in the fuse,

inserting the pellet and tightening the base plug. |

|

|

General

view of the end of the two #152 Fuse production lines.

The body of the fuse is being painted with R. C. Cement, and the safety cap joint taped. |

|

|

Building

No 30: Fuse Packing and Stenciling

Loaded fuses are brought down here from the loading buildings, placed in fuse containers and the containers packed in shipping boxes. The shipping boxes are marked with identification and shipping address. |

|

|

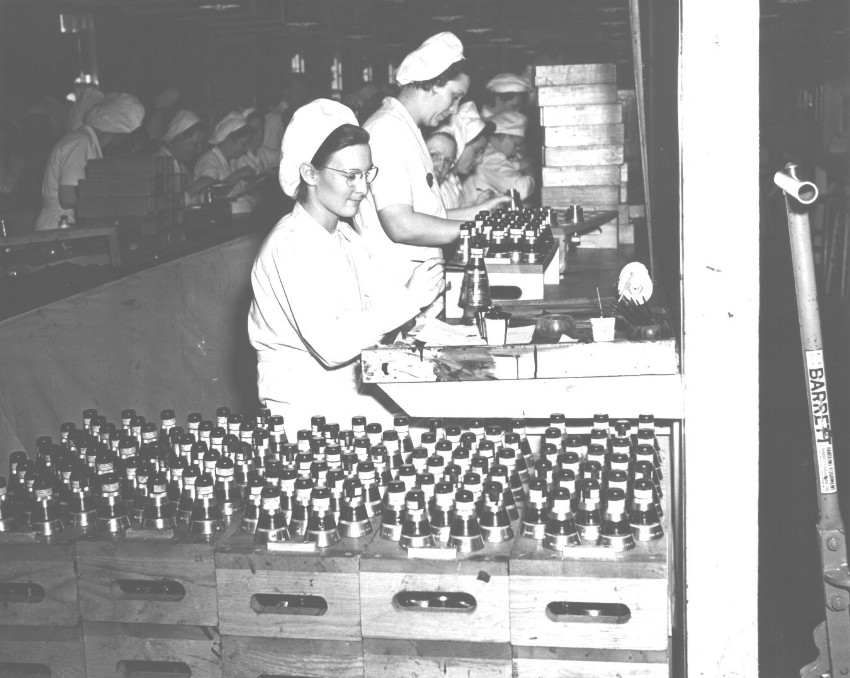

View of the labeling

and stenciling operations. After the fuses are loaded labels have

to be pasted on the caps and a stripe painted on the bodies of

the fuses. Note the trays of finished fuses in the foreground

ready for shipping.

|

|

|

Fuse Packing

The finished fuses are placed in cylindrical containers and packed in wooden shipping boxes. Note the identification stencils and the government labels on the shipping boxes. |

|

|

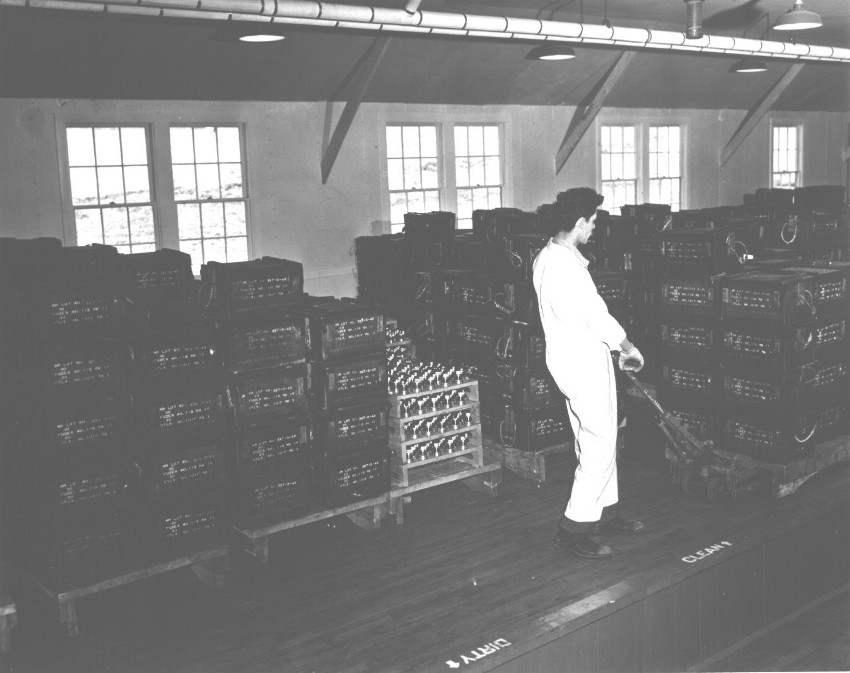

Interior view of Building

No 30 showing finished fuses in shipping boxes ready for shipment.

|

|

|

View of Fuse Proof

House in which #119 and #152 Fuses are proofed for detonation.

The left portion of the building is constructed of cement blocks

and contains the proof pot in which the fuses are exploded. The

boxes at the left of the door contain the remnants of fuses that

have been exploded.

|