|

NATIONAL MUNITIONS

COMPANY

Eldred |

|

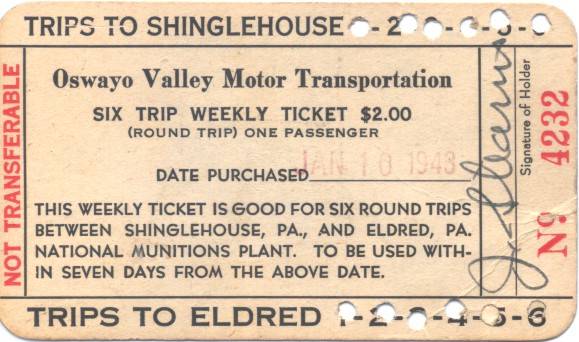

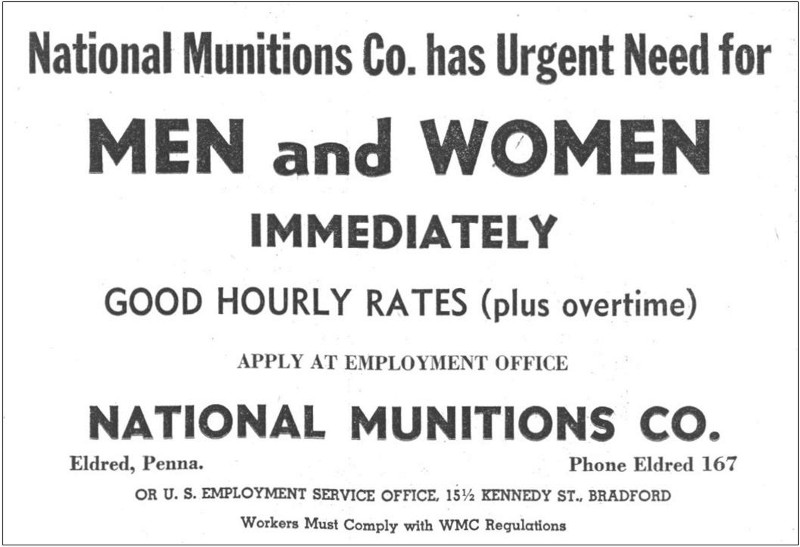

| The largest McKean County war production facility was the Eldred National Munitions Company. It was incorporated in January 1941, and located along the Artline Road in Eldred Township, just before the New York State line. The stock of the corporation was owned by the Canadian American Company, Cleveland, OH. The original fuse and shell loading plant, Plant No. 1, construction was started in February 1941, and completed in August 1941. Many additions were made to the original complex and the completion of Plant No. 4, for the loading of incendiary bombs, was finished soon thereafter. The property the company occupied totaled nearly 2,000 acres. The first tract comprised of 235 acres and then an additional 1,500 acres near and across the state line was acquired. The area was entirely surrounded by ranges of hills and two valleys known as the Big Loop and the Little Loop Hollows. The isolation and topography of the land made it especially adapted for a proving range for mortar shells. The Eldred National Munitions Company was designed as a loading plant rather than a manufacturing plant for mortar shells, incendiary grenades, thermite aerial bombs and bomb fuses. Almost all the production materials were received and completed assemblies shipped by rail on the Pittsburgh, Shawmut & Northern Railroad. The basic materials of operation—bomb shell bodies, fuse bodies, exploder bags and ammunition were received ready for loading, processing and final assembly. |

|

The 3-Inch Trench Mortar Bombs were received complete with tail fins and loaded with 80-20 Amatol, made up of 80% Ammonium Nitrate and 20% TNT. Amatol was a highly explosive material, but extremely cheaper and easier to manufacture. Amatol allowed the short supplies of TNT to be expanded considerably, without reduction in the destructive power of the shells. This was a highly attractive feature during war production when there was such high demand for explosives. The bombs were received and unpacked in the Shell Receiving building, cleaned and degreased in the Cleaning building and transported by conveyor to the Shell Loading building. Ammonium nitrate and TNT were brought down to the Screening building, screened to remove any foreign substances and transported to the Amatol Mixing building. On the third floor of the building, the ammonium nitrate was heated in heating mixers and the TNT was melted separately. These two contents were mixed with the proper proportion in Amatol mixers on the second floor, and dumped through chutes to the first floor and loaded into steam-jacketed Amatol buggies ready to be loaded into the shells. The shells were loaded in two increments and pressed to the proper density in hydraulic presses, the final press forming a cavity to receive the paper cup fuse container. The container cup was sealed in with molten TNT. From the Loading building the fuse was transported by chain conveyor to the Assembly building. Here the bombs were stenciled and striped with the proper identification markings. A booster pellet or adapter was inserted in the container cup and the fuse was screwed into place. A propelling cartridge was inserted in the tail and six augmenting charges were inserted between the fins. The tail cover was tied on, the fused bombs placed in bomb carriers containing three bombs and two of these carriers packed in an ammunition shipping case, stenciled and ready for shipment. Bomb movement through these buildings was by roller and belt conveyors. The bomb line was tooled and equipped to load 25,000 bombs per day. Pellet production of various sizes were produced by the use of pellet presses. They included the booster or adapter pellets for the bomb and the proper size of pellets for the #119 and #152 fuses. Pellets of any size were produced with these presses with the use of proper sized dies and punches. These pellet presser were operated to turn out 20 pellets per minute. The Exploder Bag building was designed and equipped for the loading of Exploder ‘B’ bags. The bags were loaded by the use of a volumetric measuring device and settled to the proper density by the use of a vibrating table designed and built at the plant. Each of the dispensing machines had a capacity of 5,000 to 6,000 bags per shift. The #119 Fuse bodies were received completely assembled and ready for loading. They were received and unpacked in the Fuse Receiving building and started down the loading line in Building 28. The fuses were first broken down or disassembled, the component parts of each fuse being kept together in one fuse block. The fuse shutter was cleaned and scraped ready for stemming. The shutters were stemmed with crystalline dense tetryl, shellacked and covered with paper discs. Two detonators, 5-grain and 3-grain, were inserted in the holders and staked, the firing channels stemmed and booster pellet inserted in the magazine. Shutter springs were tested on a spinning device to make sure that the shutter will arm between 1,300 and 1,700 revolutions. The base cap on the magazine is crimped in place. After being loaded the fuses are marked for identification, striped, proper labels attached, packed in containers and placed in fuse shipping boxes. The fuse line operated with a capacity of 5,000 to 6,000 per shift. The total capacity of the #119 Fuse lines could be increased to 15,000 to 20,000 per day when the prompt receipt of materials were available. The #152 Fuse assembly building was equipped to turn out 25,000 fuses per day. The line equipment and loading devices were similar to those of the #119 fuse production. The operational steps for loading the #152 fuse were fewer. Only one detonator, the 5-grain, is used in the fuse. The #152 fuses were loaded for assembly for the 3 Inch Trench Mortar Bomb. The employee capacity of the Eldred

National Munitions Company, exclusive of officers and salaried

executives and superintendents, was approximately 700 per eight

hour shift, or 2,100 per day on the basis of three shifts. Not

all divisions were fully tripled by three shifts and if necessary,

additional production lines could have been installed in most

divisions, increasing the employment and production capacity.

|

|

|||||

| Based on the employment schedule and production setup, the following production could be maintained as long as adequate and prompt supply of component parts and loading materials arrived as ordered. Early on during production, capacity was not met because of the failure of other government contractors to supply essential materials, particularly detonators: | |||||

In 1941, the following contracts were

received by the Eldred National Munitions Company: United States Contract: The munitions company maintained a

well equipped first aid hospital. The building contained wards

for men and women, receiving room, examination room, nurse’s

room, diet kitchen and all the necessary medical equipment and

supplies. Trained nurses were on duty during all shifts and

a physician was in attendance each forenoon, and on call at

all times. A steam laundry building was available to take all

the uniforms and overalls of all persons working with Tetryl

or TNT must be changed and laundered everyday. The men’s changing

house contained shower baths, lockers, wash fountains and a

lounge for the men. All men working with Tetryl or TNT were

required to take a bath and change their clothes everyday as

a protection against poisoning. As with the men’s change house,

there was also a women’s change building No. 32, located across

the plant road from the fuse loading buildings. It contained

a locker room, rest rooms, wash room and shower baths. Time

clocks for the women were located at the entrance. As with the

men, any women working with Tetryl, stemming, etc., must take

baths and change work clothes daily. Electric power was supplied

to the plant by the Bradford Electric Company and there were

over 10,000 feet of power lines constructed between the various

buildings. The power house used coal feeding boilers to produce

steam for the facilities. Over 9,000 feet of steam pipes, insulated

and covered with water proofing, supplied all the buildings.

The munitions company also operated its own narrow gage railroad

for transportation throughout the plant complex with over two

miles of track. Three Plymouth gasoline locomotives, models

RL & RLH, operated with anti-fire safety features of the exhaust

through water. There were fifteen specially designed tram cars

for hauling the materials.

|

|